Horizontal Stabiliser 08-11 to 08-12

These stages involved riveting the nose ribs into the skins, then riveting in the spar assembly. I know some very clever people have done all this solo, and I take my hat off to them! Tim helped out for several sessions with this, and we still found it hard to set all the rivets nicely.

Nose Ribs

First job was to rivet in the nose ribs after dropping the skins into the little stands.

The first rivets did not go well at all, and so we took a short break and tried to work out why they were being awkard. Other people have highlighted that any jointing compound on the rivet surfaces can make them skew slightly on setting if not perfectly aligned on the bucking bar. After wiping off excess compound the pesky things started to set much better.

Spar Assembly

JC5 applied ready to drop the assembly into the skins.

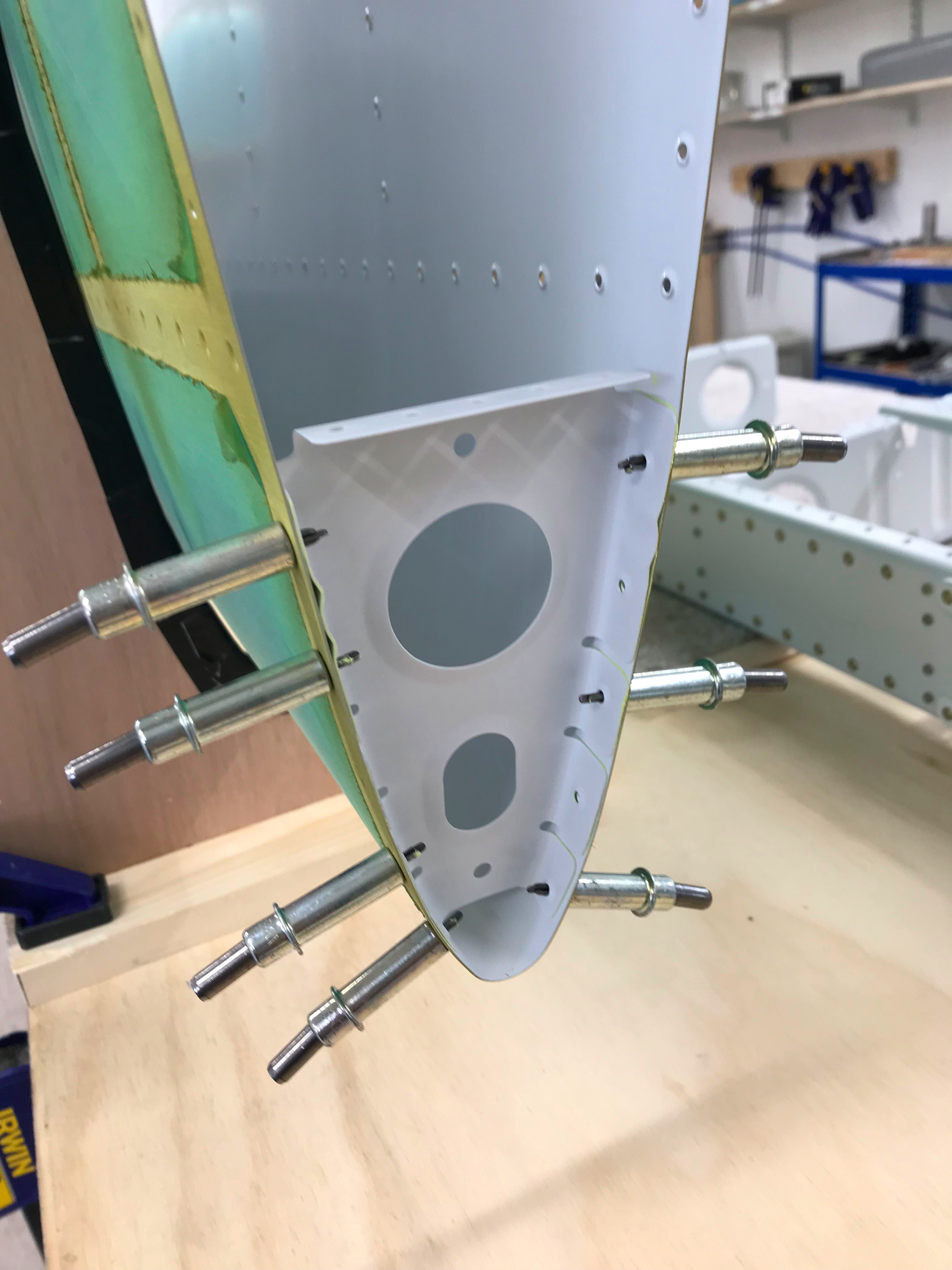

Then clecoed together.

Lots of rivets

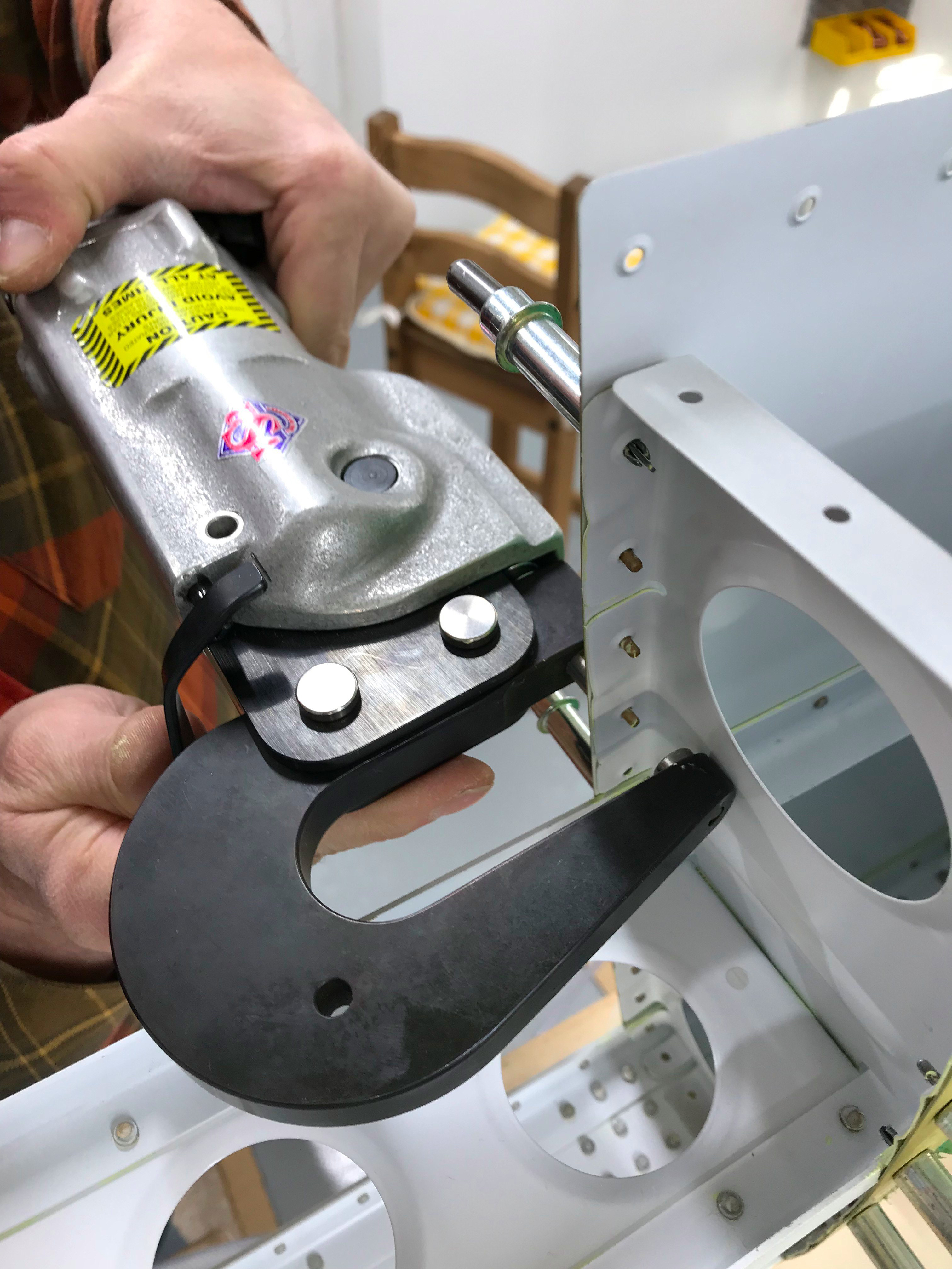

We operated the gun at about 40 PSI, trying to get the job done without distorting the skins. Tim on the bucking bar, me on the gun. Some rivets awkard to access around the stringer areas. Using the Cleaveland Tungsten Bucking Bar, and the cheaper Footed Bucking Bar for the occassional awkard access rivet.

Skin Edges

Whenever possible used the pneumatic squeezer to get the rivets around the edge of the skins. Just a few up these inside edges which needed the gun due to access issues.

Rear Spar

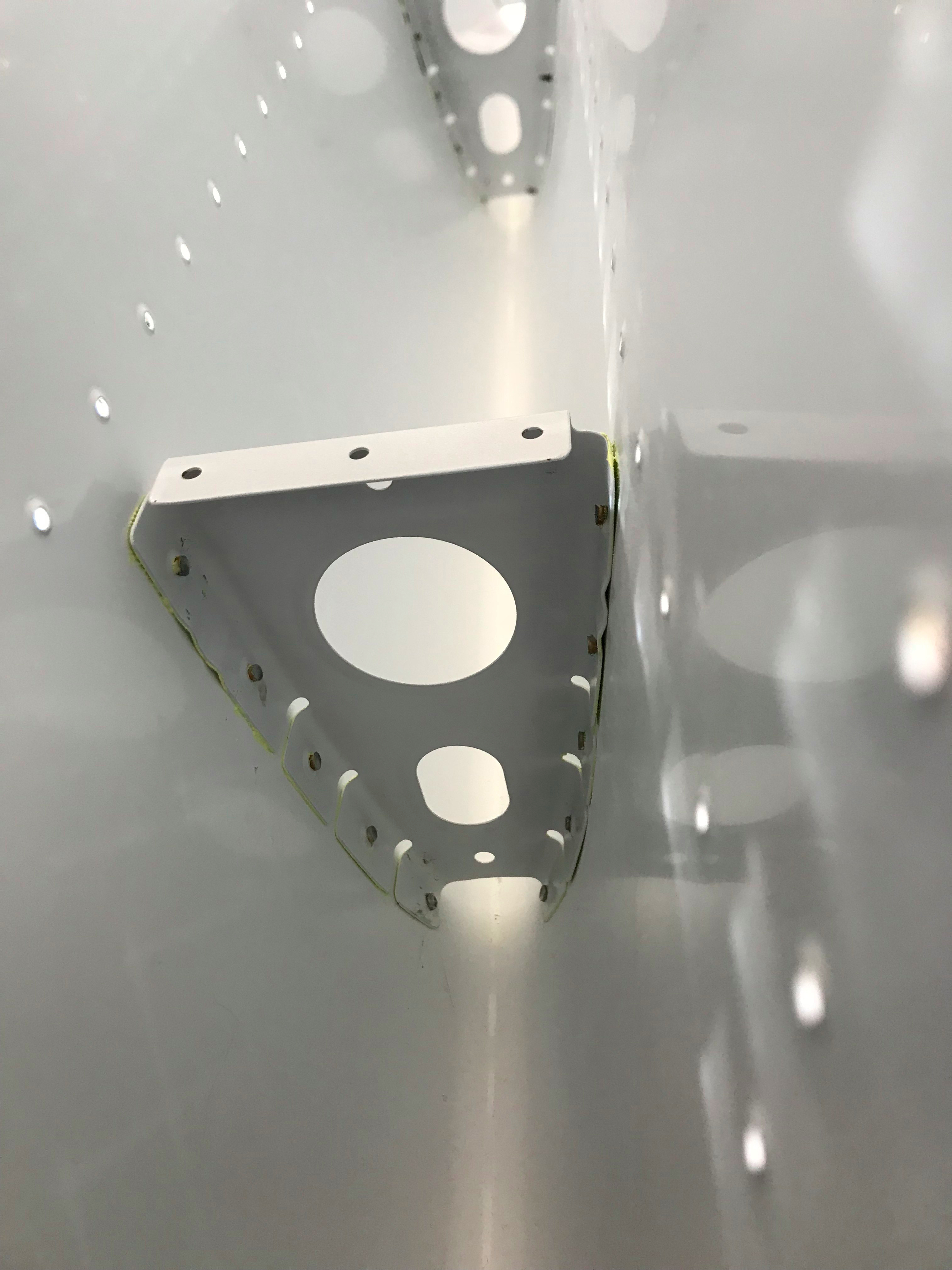

Rear spar ready to be dropped into the structure. Van’s make a big deal of checking the orientation! I feel very sorry for builders who have accidently riveted this spar in upside down. We double and triple checked this, couldn’t face a disaster!!

Nearly Finished!

Van’s suggest that the rivets attaching the Front Spar Assembly Inside ribs to the inside Nose Ribs are left until last to improve access. So that’s what we did, but have run out of time. Hopefully a quick job next session.

2 comments on Horizontal Stabiliser 08-11 to 08-12

What is the “JC5” stuff you refer to in this post. I take it it is some kind of adhesive? Vans doesn’t call for it, do they? Would you use it again?

Thanks

Your blog is real convienent and helpful.

(I’m priming my components too. Think it is a pain but the smart thing to to.)

Frank Dressel

Smithton IL

Hi Frank … “JC5A is a one-part, non-curing, corrosion inhibitive compound. It can be applied to removable fasteners and assemblies to prevent the ingress of moisture and to provide protection from galvanic corrosion. JC5A is paste-like in consistency, allowing for easy application by brush, roller or spatula.” … Here in the UK our build inspectors are keen to see metal aircraft constructed with as much corrosion protection as possible, and I was advised to use JC5A or Duralac. I’ve used JC5 throughout the construction to give the plane as much longevity and second hand value as possible here in the UK.