Engine Timing

I made sure the PMag Ignition Harness was routed correctly, making sure no individual cables were touching each other as advised in the E-MAG installation manual.

We are using the E-MAG Auto Leads with Denso IKH27 Spark Plugs screwed into long reach adapters.

If the cables touch it can cause them to be inductively coupled, which is not an issue with shielded aircraft cables as found on normal magnetos.

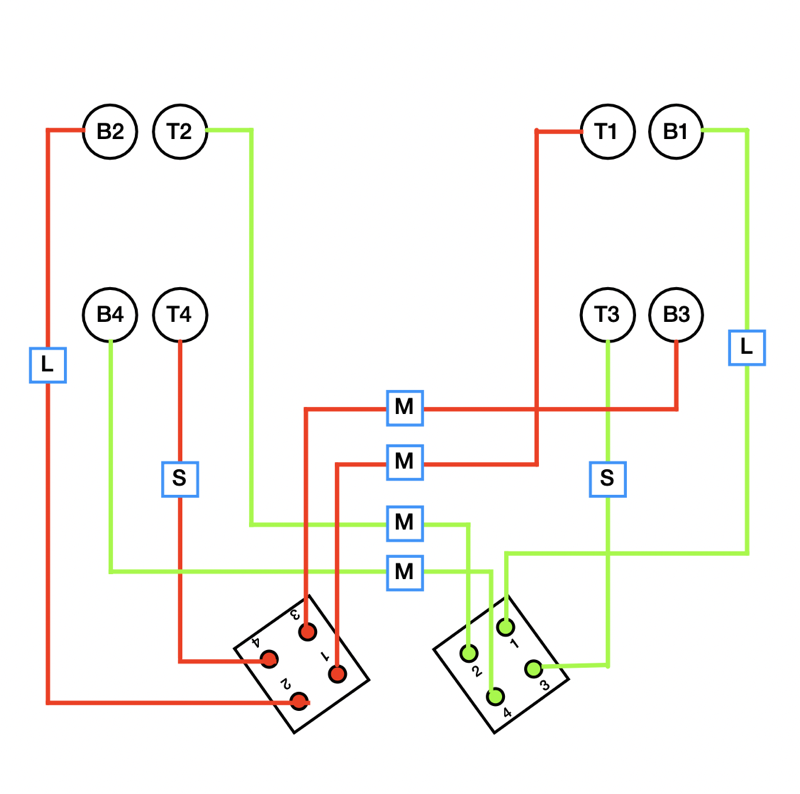

I used the schematic I had produced during the installation to double check all the connections.

The PMag control plugs are temporarily removed for safety. We also removed all the plugs ready to check the system by a pull through test.

The first task is to accurately position the propeller with the No 1 cylinder at Top Dead Centre (TDC).

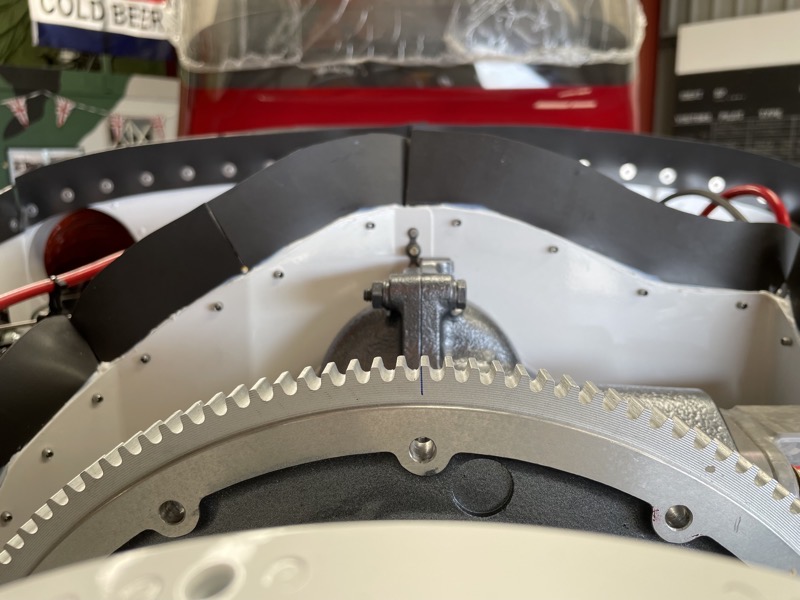

There are markings on the rear of the starter ring to assist with this task, and it doesn’t matter whether it’s a firing or exhaust stroke.

If this was an engine with a recommended magneto timing of 25 degrees BTDC, this is the position to set the PMag timing.

The Pmag automatically times it at 25º BTDC if the timing is activated in this position.

But the IO-390 has a recommended magneto timing of 20 degrees BTDC.

So, the Propeller has to be rotated in the normal direction a further 5º …

… which is actually the same as two starter teeth.

So when the timing is activated in this position the PMags will actually be timed at the required 20º BTDC.

The PMags are powered up whilst the P-Leads are grounded, which puts them into setup mode.

This was easily achieved with our configuration since we have OFF/ON/TEST mag switches … when OFF the mags are grounded but are receiving aircraft power. The momentary TEST position leaves the P-Leads ungrounded but removes power.

There are a series of LED light signals on the units to monitor at this point, needing a mirror to see.

The timing is activated by a firm puff into the MAP sensor tubes with a pressure of at least 0.5 PSI. Apparently this is similar to the pressure needed to sound a trumpet. Since neither of us has ever blown our own trumpets, Tim went red in the face to ensure a good result!

Once all done we re-fitted the control plugs and connected the harness to the spark plugs, making sure they were earthed to the engine.

By pulling through the engine you can check they are firing in the correct position. This is where the E-MAG installation manual is confusing, but a phone call to EMagAir soon shed some light … the manual will be updated apparently.

During the start cycle the plugs have a starting lag of about 4º after TDC … but since on a 390 you have already retarded it by 5º during the setup, the plugs on a 390 should fire about 9º after TDC during the pull through test.

We had already filled the engine with 7 US Quarts of Aeroshell 100 Straight Oil, and also primed the oil cooler.

The last task to get the engine ready for it’s first start was to pre-oil.

About three short start cycles with a plug removed from each cylinder produced a healthy 32 PSI oil pressure … the video below shows the last cycle, under the watchful eye of Pete, our knowledgeable LAA Engineering inspector.

Running out of excuses not to try a start!