18-05 Drain & Fuel Cap Flanges

Before staring to install the ribs, the Fuel Cap and Drain Flanges are installed.

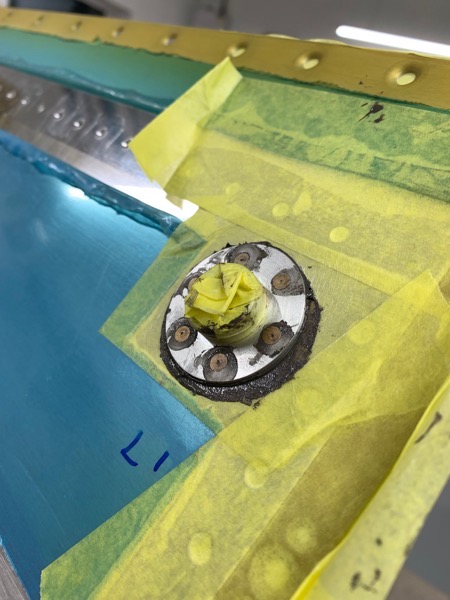

V112 Drain Flange

After a “dry” run it was obvious the rivets could be reached with the squeezer, so an easy job to install once all masked up.

Both ends of the rivets thoroughly covered in Proseal.

The hardest bit was to make sure no Proseal had seeped onto the internal thread. Well obviously it did, but nothing some tissue & MEK couldn’t sort out.

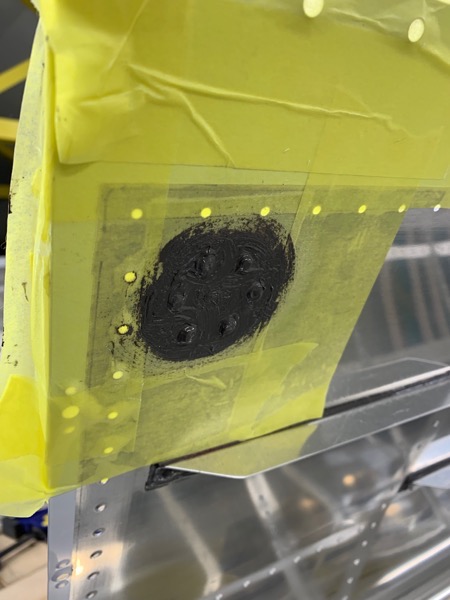

Here it is after removing the masking and cleaning up. Although it takes longer to mask everything, the benefit comes by not having to worry about keeping the Proseal under control, saving time during the assembly..

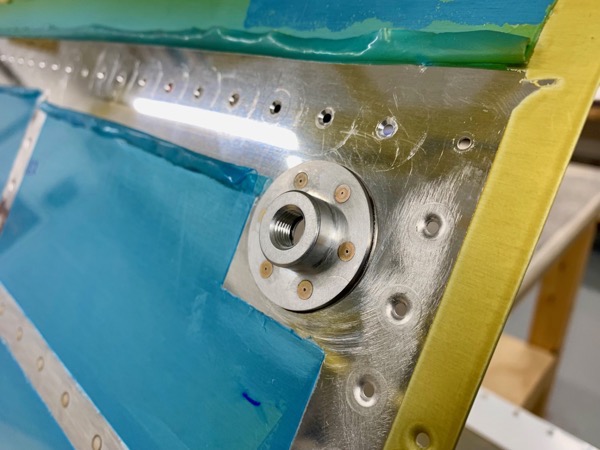

Fuel Cap Flange

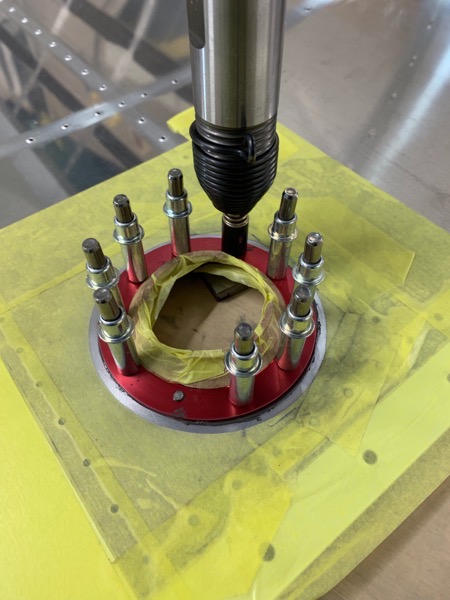

I decided to back-rivet these rivets. Although the flange has a curved surface, I found it straightforward to jig the skin so as to keep the relevant rivet flat on the plate.

Here you can see the corner of the back-rivet plate. Nothing got too dirty with Proseal since I had put some rivet tape over the rivet factory heads.

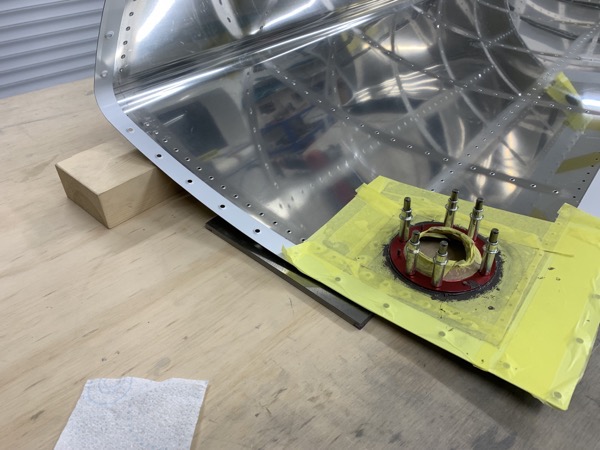

It would be very easy to forget to rivet on the Vent Line Clip … I placed the clip adjacent to the work area and managed to remember!

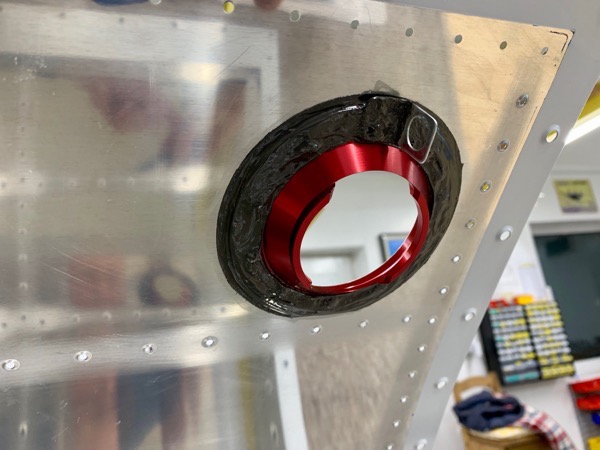

Anyway, here is the underside of one of the flanges once the shop heads were Prosealed and masking removed.

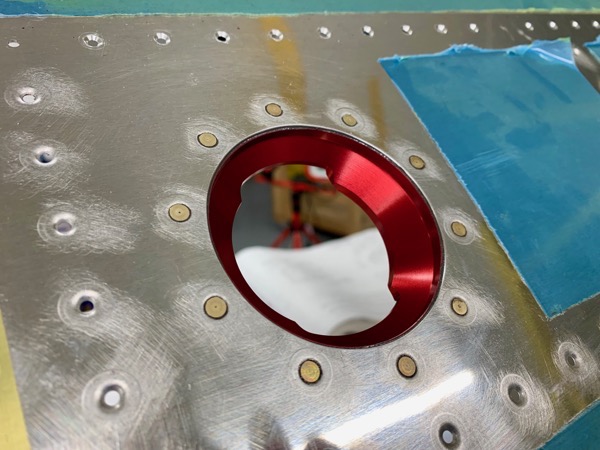

And the final result from the top. It all takes much longer dealing with the Proseal, but it’s not too bad. I’m trying to enjoy it! : )

Ribs next.